Welcome to WedgeNMoil.Kr

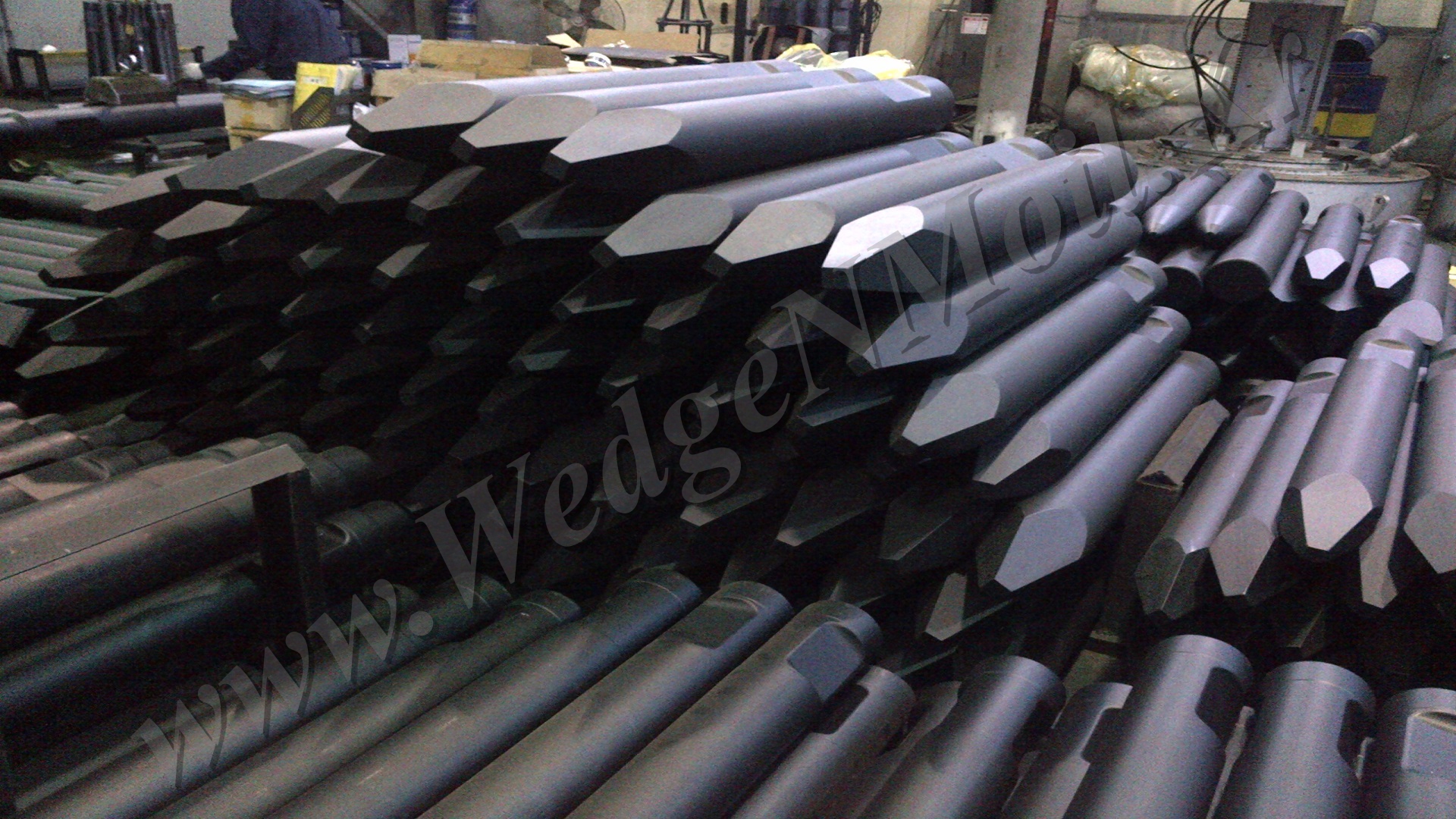

A trusted Korean supplier of Wedges, Moils, Blunts, and Pistons for Hydraulic Hammer - delivering quality and reliability worldwide.

About

Find Out More About Us

WedgeNMoil.Kr

is one of the largest and most trusted suppliers and exporters of high-quality demolition tools in Korea.

-

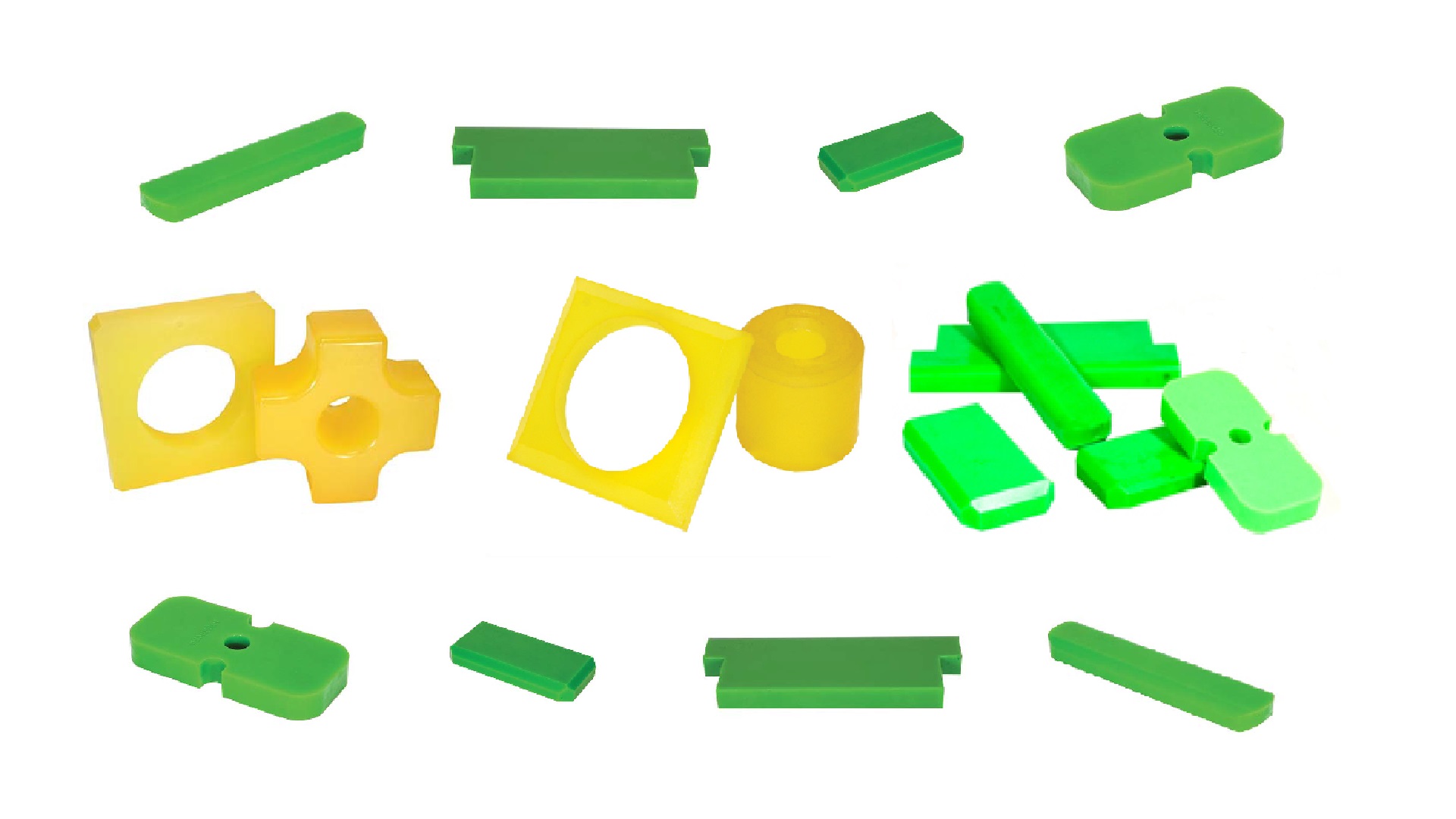

Our Products

We specialize in producing a wide range of demolition tools and components for hydraulic breakers, including : Wedge, Moil, Blunt, Conical, Wide Moil, and Piston for Hydraulic Breaker. Use in Rock Breaking, Quarrying, Construction, Civil Engineering and Demolition.

-

Quality & Technology

Quality is not just a standard — it’s our philosophy. Every product undergoes strict inspection, precise heat treatment, and rigorous testing before shipment. Our engineers continuously develop new designs and materials to extend tool life and improve performance under the toughest working conditions.

We provide one of the widest product ranges in the industry, designed to meet the needs of hydraulic breaker (hammer) users worldwide. Our tools are manufactured using premium raw materials, advanced technology, and - most importantly - the craftsmanship and pride of our skilled engineers. We are committed to excellence in manufacturing, quality control, and continuous research to deliver the highest performance tools in the market.

Material Selection

High-grade alloy steels such as 40Cr, 42CrMo, or equivalent materials are used as base stock. These steels provide an appropriate balance of hardness, toughness, and heat resistance, which are critical for absorbing repetitive dynamic loads. Material specifications are verified through chemical composition analysis and mechanical property testing prior to processing.

Cutting and Forging

Steel bars are cut to the required blank length according to product specifications. The cut blanks are then heated to 1,100–1,250 °C in a controlled-atmosphere furnace to achieve plasticity suitable for deformation. Forging is carried out using closed-die or open-die hammer forging, depending on production volume and tool geometry. This process improves internal grain flow, reduces segregation, and enhances structural integrity.

Machining

and Dimensional Processing : After forging, scale and surface irregularities are removed by shot blasting. Machining ensures uniform fitment with the breaker housing and precise geometric conformity across production batches.

Heat Treatment

Heat treatment is a critical process that determines the tool’s final mechanical properties. It consists of the following stages : Austenitizing and Quenching, Tempering. The goal is to achieve a hard tip (HRC 50–55) for wear resistance and a tough body to prevent premature fracture under impact.

Surface Finishing and Marking

Post heat-treatment, the tools undergo sandblasting or shot blasting for surface cleaning and uniform texture. A protective coating (e.g., black oxide, oil film, or industrial paint) is applied to prevent corrosion during handling and storage. Each tool is laser-engraved or mechanically stamped with product code, batch number, and size specification for traceability.

Quality Control and Testing

Quality assurance is conducted throughout the manufacturing process in accordance with internal and international standards. Key inspections include : Hardness testing, Dimensional inspection, Crack and defect detection, Impact performance testing. All test results are documented for traceability and continuous process improvement.

Packaging and Storage

Finished tools are coated with rust-preventive oil and packaged in protective materials such as plastic sleeves, corrugated boxes, or wooden crates. Packaging configurations vary depending on tool dimensions and customer requirements. Proper storage conditions (low humidity, stable temperature) are maintained to ensure long-term preservation of tool quality.

Summary

The production of Wedge and Moil Point tools integrates metallurgical control, precision machining, and advanced heat treatment to deliver superior mechanical performance. Strict adherence to process parameters ensures : Consistent hardness and impact resistance, Dimensional uniformity, Extended operational lifespan under high-load conditions. This process framework supports reliable tool performance in demanding construction and mining environments.

Services

Check Our Wedge N Moil Points

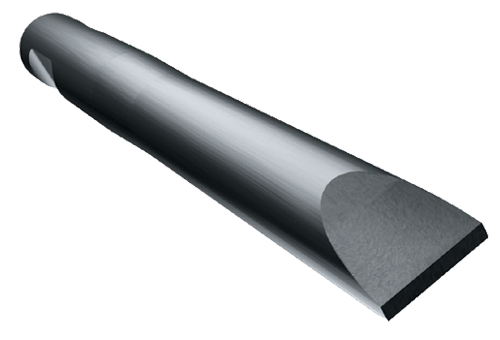

Wedge Point

A flat, chisel-shaped tool designed for splitting and cutting concrete or rock. Ideal for wall demolition, trenching, and slab removal. Provides strong lateral force for controlled cracking.

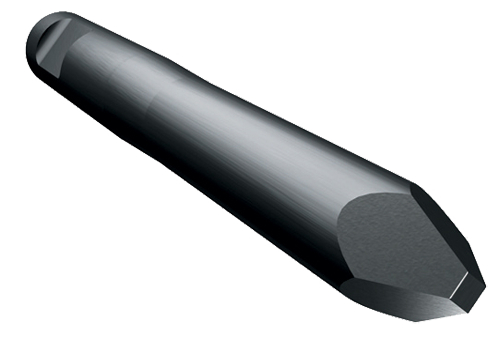

Moil Point

A sharply pointed tool for concentrated impact and penetration. Used to start cracks or break hard rock and concrete. Suitable for quarrying, mining, and general demolition.

Blunt Point

A flat, round-end tool that delivers pure crushing force without cutting. Used for breaking oversized rocks, surface compaction, and secondary reduction. Provides long service life under heavy impact.

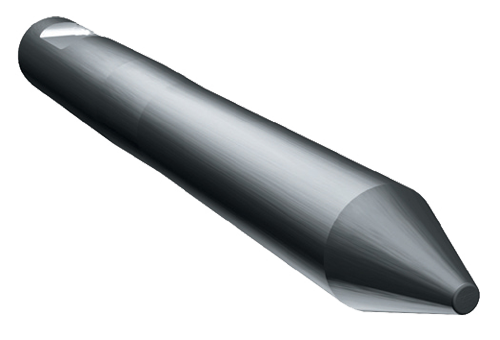

Conical Point

A cone-shaped tool offering balanced penetration and durability. Effective for breaking medium to hard rock, concrete, and frozen ground. Its shape reduces jamming and ensures even wear.

Wide Wedge Point

A broad chisel blade designed for large-area removal of materials. Commonly used in road maintenance and surface demolition. Maximizes coverage and work efficiency.

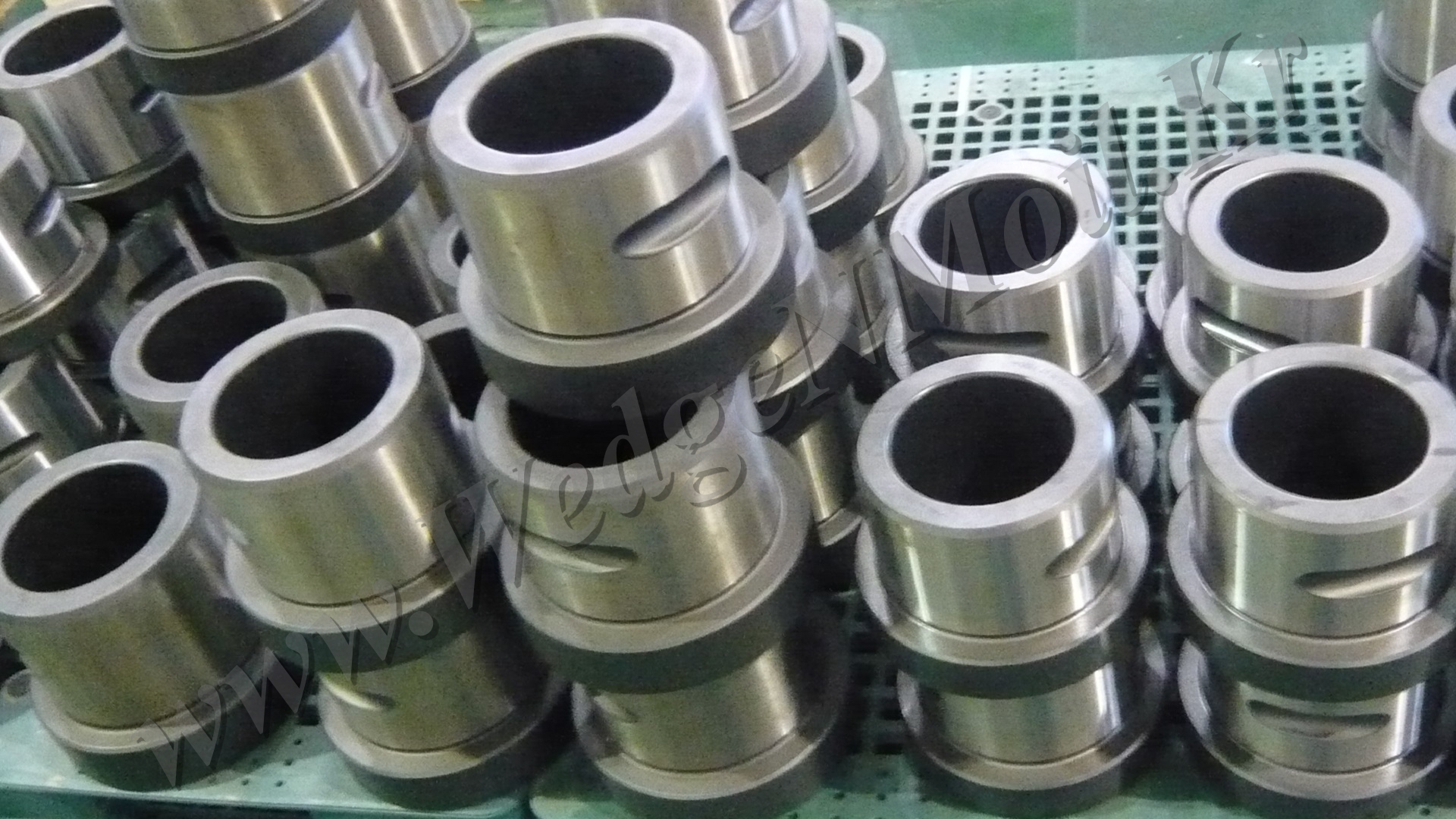

Hydraulic Breaker Piston

The core impact component of the hydraulic breaker. Converts hydraulic pressure into mechanical striking energy. Made from high-strength alloy steel for durability and consistent performance.

Product

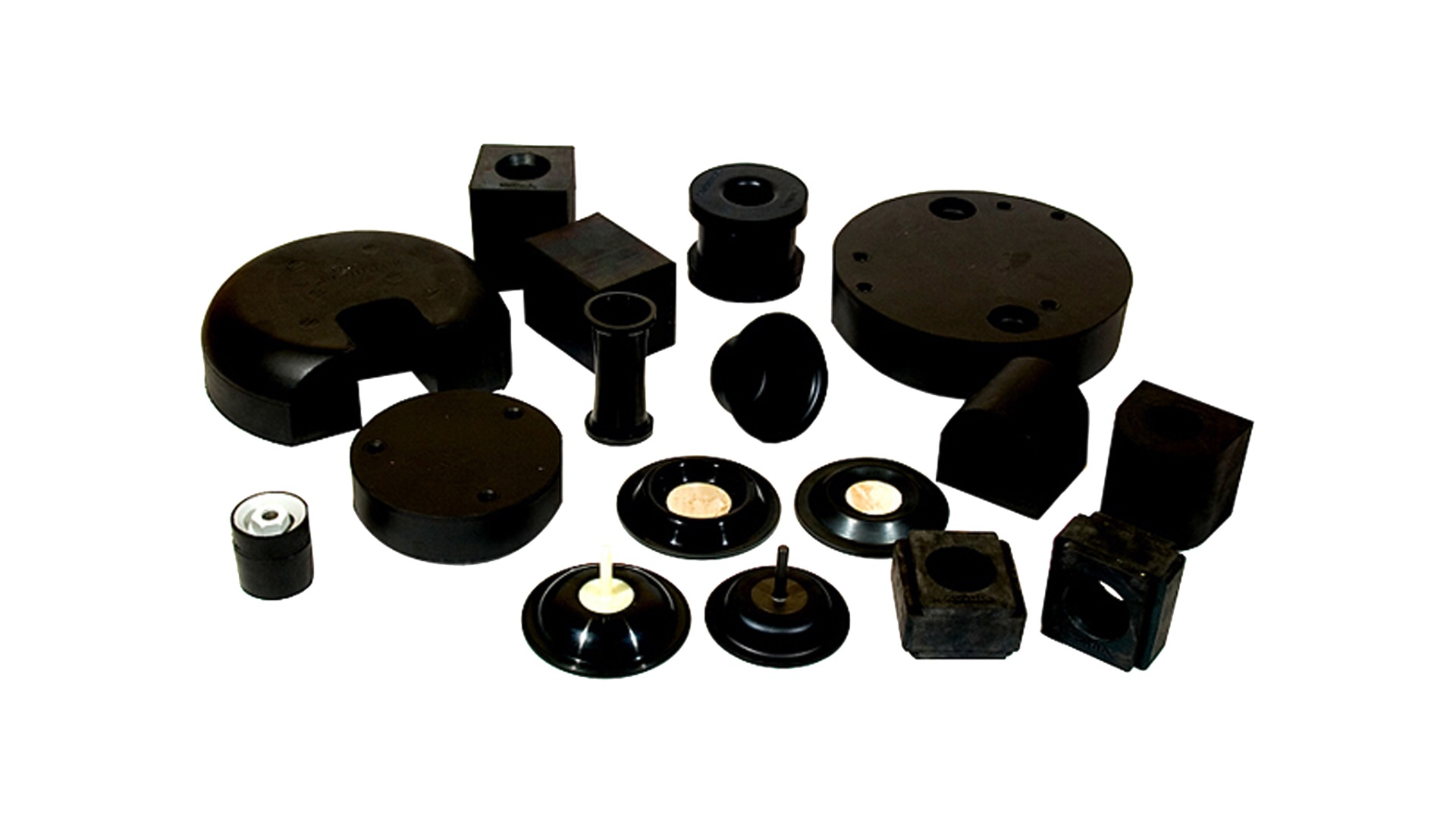

Check Our Products

- All

- Points

- Piston

- Breaker parts

- Seal Kit & Diaphragm

F.A.Q

Frequently Asked Questions

What are Wedge and Moil tools used for?

Wedge and Moil tools are used for rock breaking, trenching, concrete demolition, and other heavy-duty applications when attached to hydraulic breakers (hammers).

What is the difference between a Wedge and a Moil?

A Wedge (Chisel) has a flat, sharp edge — ideal for digging, trenching, or cutting through layered rock.

A Moil (Pyramid) has a pointed tip — perfect for general breaking work and penetrating hard surfaces.

What materials are Wedge and Moil tools made from?

Our tools are made from high-grade alloy steel(SAE4140M2, SCM440), heat-treated for maximum durability and wear resistance, ensuring long service life even under extreme working conditions.

Can you customize the size or design of the tools?

Yes. We can manufacture customized tools based on your breaker model, application, or working environment. Please provide the breaker brand and model for accurate fitting.

How can I extend the lifespan of my Wedge and Moil tools?

Regular lubrication, proper alignment, and avoiding overheating during operation help extend tool life. Using accurate wedge and moil points also ensures the best performance and durability.

Do you export these tools internationally?

Yes, we export worldwide. Our products are trusted by clients across Asia, America, Europe, Middle East and Africa for their precision and performance.

Are these tools compatible with all hydraulic breakers?

We manufacture Wedge, Moil, Blunt, Conical, and other types compatible with most major hydraulic breaker brands. Custom fitting is available upon request.

What quality control processes do you follow?

Every product undergoes strict inspection, heat treatment verification, and performance testing before shipment to ensure consistent quality.

What’s the lead time for orders?

Standard lead time is about 10 - 14 days after payment confirmation, unless otherwise noted. For large or custom orders, please contact us for an exact delivery schedule.

How can I place an order or get a quotation?

You can contact us directly via email. Please include your tool type, breaker model, and required quantity for a quick and accurate quotation.

Contact

Need Help? Contact Us